The quality of the installation and commissioning of the pump directly affects the normal operation of the pump, as well as the service life and performance parameters of the pump.

1. Prepare

(a) The surface of the foundation shall be level and firm, and the surrounding surface of the anchor bolts shall be level and firm.

(b) The site has been cleaned and there is sufficient space to transport and unload parts or the entire equipment.

(c) Use appropriate means of transport to transport the pump and related accessories to the installation site, and carefully remove them.

Packed to prevent damage to internal parts.

(d) Parts left on site must be properly preserved against moisture, contamination and damage.

2. Pipeline installation

(a) When selecting the diameter of the suction pipe, the flow velocity in the pipe should be kept v=1~2.2m/s to reduce resistance and ensure

The system has sufficient effective NPSH NPSHa.

(b) A gate valve (or other type of valve) and a check valve should be installed in the discharge pipeline. The check valve should be installed in

between the pump and the gate valve.

(c) The inlet and outlet pipes of the pump and the associated valves should have separate supports to minimize the effect of the pipes.

load on the pump.

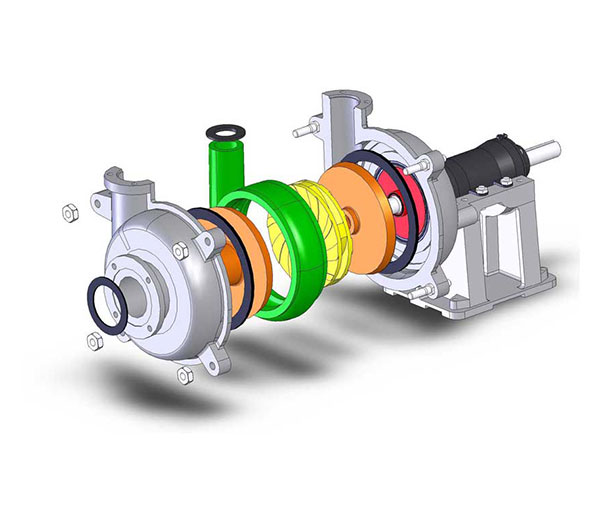

3. Pump set installation

(a) Check whether the pump and motor are damaged, check the unit foundation and anchor bolt holes and anchor bolts.

(b) Hang the foundation pad (some pumps do not need it) on the foundation, put on the anchor bolts, screw on the nuts,

Find the level, and the level tolerance is controlled within the required range.

(c) Secondary grouting, pay attention to levelness during grouting. After 5~6 days of cement drying, recheck the level

Spend.

(d) Put the pump and motor on the foundation pad, use wedges or pads to level, and use a level to align.

(e) Correct the concentricity of the motor and the pump shaft by checking the concentricity of the outer circle of the motor and the pump coupling.

(f) There shall be the clearance value given in the installation drawing between the pump and the motor coupling.

(g) Install all pipes, such as water seal water pipes, cooling water pipes and other components.